Heat treatment of structural components and chassis parts to T6

- Solution heat treatment

- Air quenching

- Artificial ageing

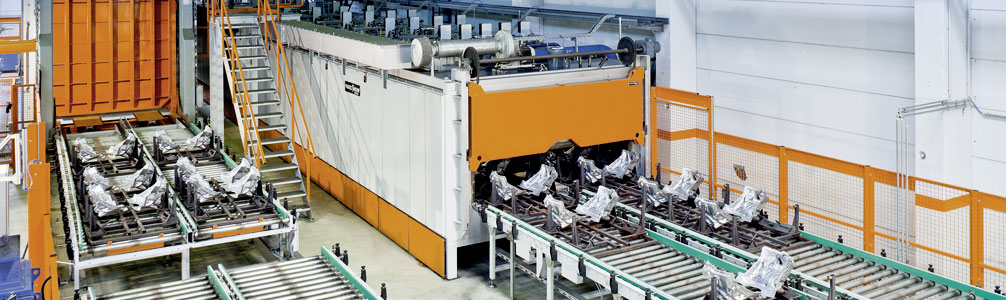

Hanomag Aluminium Solutions uses a large continuous T6 heat treatment furnace with air quenching to heat treat aluminium structural components and chassis parts and obtain the mechanical properties demanded by the car industry. Special component-specific jigs developed and built by Hanomag are used to minimise the component distortion inherent in the process and thus reduce the amount of truing that needs to be carried out afterwards.

The obligatory checks of mechanical properties at different stages of the process are carried out using tensile and hardness testing in the company’s in-house laboratory.

Moreover, Hanomag Aluminium Solutions is currently investing in an additional heat treatment plant with a modular design. From the autumn of 2012 onwards, Hanomag will then be able to quench thick-walled chill-cast chassis or engine components in water or polymer. It will also be possible to air-quench thin-walled cast structural components with the new unit, either as an alternative to the existing continuous-process plant or to increase its capacity. Thanks to their modular design, the furnaces can be retrofitted or extended in accordance with specific order requirements.